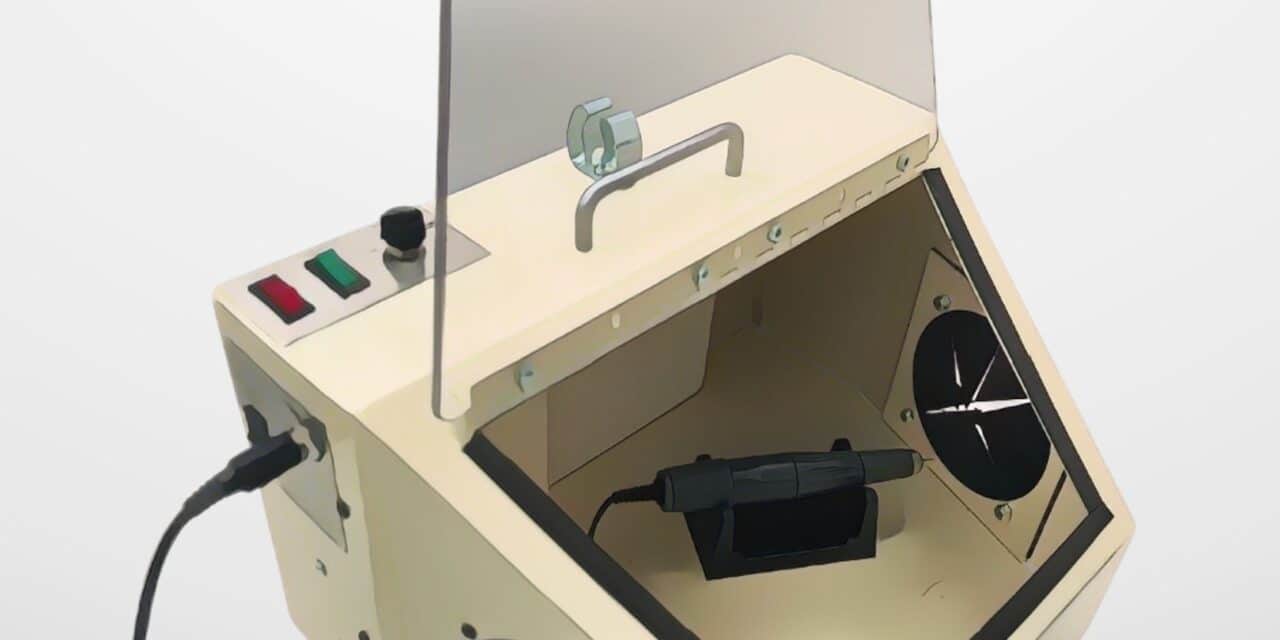

The new V35E enclosed micromotor handpiece is designed to improve safety and efficiency when finishing 3D-printed oral appliances.

Buffalo Dental Manufacturing has launched the V35E, an enclosed micromotor handpiece designed to capture debris and improve safety when grinding, trimming, and adjusting 3D-printed oral appliances.

System Addresses Particle Exposure

The V35E is intended to address concerns about exposure to harmful particles, volatile compounds, and residual toxins released during the finishing process of 3D-printed materials. The unit’s fully-enclosed system captures debris and circulates it through an integrated filtration system, helping to protect technicians and clinicians and maintain a cleaner workspace.

“The V35E is built for today’s labs and dental offices where speed, precision, and safety must go hand in hand,” the company says in a release. “This versatile innovation gives technicians and clinicians the confidence to work efficiently with 3D prosthetics without compromising on health, safety, or performance.”

Features and Workflow

According to the company, the V35E offers high-torque performance with precise speed control to enable faster workflows. Key benefits highlighted by Buffalo Dental include advanced containment of dust, fumes, and toxins, and a high-torque motor for greater efficiency. The unit also features a compact, ergonomic design to reduce operator fatigue and durable construction intended for busy dental lab environments.

Availability

The V35E is available immediately through authorized dealers and distribution partners. More information can be found on the company’s website.

Photo: Buffalo Dental Manufacturing