With the introduction of its new digital treatment design tool ClearPilot and multi-layer, high-performance plastic ClearQuartz, ClearCorrect looks for a competitive advantage in the clear aligner market

By Greg Thompson

In the intensely competitive world of clear aligners, legal tussles raged for more than two decades as patents expired and companies vied for market share. In recent years, ClearCorrect, Round Rock, Tex, an established clear aligner brand, has patiently added resources, boosted efficiencies, and successfully navigated those legal landmines.

Three years ago, the Switzerland-based Straumann Group acquired ClearCorrect, bolstering capabilities and clearing the way for growth at a time when simmering legal battles had all but ended. “We do a legal and regulatory review when we come to something new,” says Camila Finzi, executive vice president of orthodontics at the Straumann Group. “It’s all quiet on the legal front.”

Own the End-to-End Process

With a clear path ahead, Straumann created an orthodontic business unit (BU) based in the United States to speed up manufacturing and drive growth. The company also acquired Bay Materials, a U.S.-based manufacturer of thermoplastic used in clear aligners, in October of last year.

“That helped us to bring innovative materials to market,” Finzi reveals. “We are one of the few who own end-to-end processes. We own the manufacturing of the material that goes into our aligners, and that’s not the case for many of our competitors. I see this as a competitive advantage.”

A newly created “close integration” with 3Shape, an intraoral scanner manufacturer with U.S. headquarters in New Providence, NJ, allows clinicians to submit a case directly out of the 3Shape database. “We are developing the same type of integration with other intraoral scanners,” Finzi says. “We expect that our providers will see improved times and speed gains.”

The Straumann Group Orthodontic Business Unit now has three manufacturing plants—one in the United States, one in Brazil, and one in Germany. With three sites, Finzi contends that “we are producing aligners faster than most of our competitors who just have one location—and we’re doing it with better materials and faster turnaround times.”

Expanding In-House Capabilities

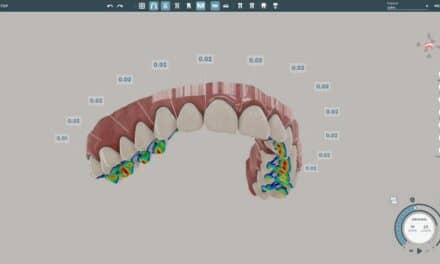

The introduction of a new software called ClearPilot, a digital treatment design tool, is also expanding ClearCorrect’s considerable in-house capabilities. Specifically, ClearPilot is ClearCorrect’s tool for reviewing and approving clear aligner cases.

Using a treatment simulation, specifically a 3D sequential animation of teeth movement via aligner treatment (provided by ClearCorrect’s technicians), the system records clinical photos, impressions/scans, and x-rays. The tools in ClearPilot then help clinicians to create ideal treatment outcomes for their patients.

“You can access ClearPilot online via the ClearCorrect Doctor Portal,” Finzi explains. “Following case submission, you’ll receive a notification when the treatment setup is ready for review in ClearPilot. Within the ClearPilot platform you’ll find a number of intuitive graphic combinations of action icons, a main display window with the treatment simulation, a tooth movement chart, superimposition, dropdown menus and panels, and other tools and information all arranged to enhance your experience.”

A New High-Performance Plastic

ClearCorrect has been busy with an impressive flurry of activity, executing on some major initiatives: business unit creation; acquisition of Bay Materials; integration with 3Shape; introduction of ClearPilot; and most recently the launch of ClearQuartz, a new multi-layer, high-performance plastic.

“We just started manufacturing using ClearQuartz on August 14,” Finzi enthuses. “This will become available globally following regulatory approval where it’s necessary. It’s available in the United States and some other important markets already, and by now customers are receiving their aligners in this new material. This product offers high stress retention properties, excellent visual clarity, and remarkable stain resistance.”

As it stands now, ongoing treatments that have already shipped will not be replaced with appliances made with ClearQuartz. Instead, ClearQuartz will be used on new cases and cases mid-treatment. “There is no price increase associated with the release of ClearQuartz,” Finzi assures. “There are no negative effects on clinical outcomes, and the aligners are made without BPA or phthalates; and the material has been extensively tested for biocompatibility.”

Considerable Momentum

These initiatives all add up to considerable momentum, and Finzi is confident that the initiatives will ultimately translate to high usage, positive numbers, and satisfied patients. Speed, materials, software, and workflow are all negotiable.

Finzi explains: “Clinicians may have a point of dissatisfaction with their current brand. We are working with that in mind and ensuring that customers can be delighted to work with us. Our aligners are easier to produce, and we are gaining speed in the manufacturing process. We manufacture here in the United States, and it’s easier, cheaper, and faster to get to all major cities in the U.S. We are continuously working on automation and process improvement. We have very aggressive timelines.” OP

Greg Thompson is a freelance writer for Orthodontic Products.