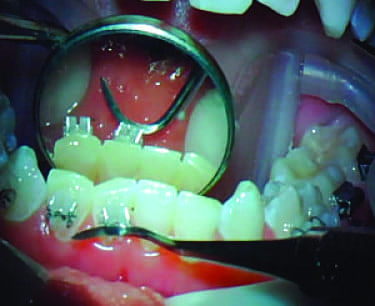

Figure 1: Brackets precoated with APC Flash-Free Adhesive require less force to place on the tooth because there is no flash to extract.

Every busy orthodontist knows that getting back even a few extra minutes in a day can be invaluable for productivity. For me, the ultimate frustration is when I look at my schedule and see red—because a red appointment means it’s a repair. The last thing I want to do after bonding ?28 brackets is have a patient return due to a bond failure.Not only do repair or emergency appointments require more time from the patient and the orthodontist, but it also can mean that the patient loses confidence in the practitioner. In order to keep these types of appointments to a bare minimum, it is important to learn and evaluate new materials to challenge current perceptions on orthodontic procedures.

Mohammad Razavi, DDS, is in private practice in Kanata, Ontario, Canada. Prior to relocating to the Ontario region, he practiced orthodontics for 5 years in the Cleveland area, serving as the orthodontist for the Cleveland Browns and on the Craniofacial Team at the Cleveland Clinic. Currently, he is an assistant clinical professor and founder and former director of the Skeletal Anchorage Clinic at Case Western Reserve University. Razavi received his DDS degree and his Orthodontic Certificate and MSD from Case Western Reserve University.

When I took over my own practice 6 years ago, I evaluated our products and procedures to ensure we took advantage of advancements in the industry to improve our productivity and our patients’ perception of their treatment. In 2012, I started using the APC™ Flash-Free Adhesive Coated Appliance System from 3M Unitek. I’ve found that this system is inherently efficient. It enables a significant reduction in the number of steps involved in bonding, and introduces a number of ancillary benefits that we never expected.

Simplified Procedure, Unexpected Benefits

Most orthodontists identify with a traditional method of bonding brackets, which involves applying adhesive to the bracket, positioning, applying force to extrude additional adhesive, and the removal of flash. This flash removal step has become second nature—an all-too-familiar part of the bonding process. However, advancements in adhesive and materials science have led to a process that eliminates this step, while maintaining bond strength.

The APC Flash-Free Adhesive System utilizes a nonwoven mat that is preplaced on the bracket and infused with lightly filled resin with a primer-like consistency. Rather than forming “clumps” at the bracket periphery, it wets the tooth surface to form a meniscus or fillet. This requires less force to position and fully seat the bracket onto the tooth (Figure 1). When seating the bracket onto the tooth, you will feel the mat squeezing the excess resin out and around the bracket margins.

Figure 2: Brackets coated with traditional adhesives, like the image above, require extra time to remove excess flash, a process that can also move the bracket out of position.

Unlike other brackets, it is not necessary to clean up the flash. The leftover resin is a translucent adhesive, which actually protects the teeth from acid erosion during treatment. Initially, this confused me. My first instinct was to remove this leftover resin, as I normally do with flash. However, the beauty of this process is that no additional steps or time are needed after bracket placement on the tooth, and that the patient actually benefits from this meniscus layer.

An additional benefit is that because each bracket comes pre-coated with adhesive, there is no concern of bumping the bracket out of place while cleaning up the flash with your scaler (Figure 2). This ensures that the initial bond strength is not compromised.

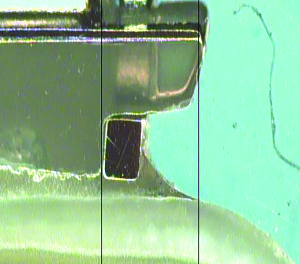

Of course, excellent aesthetics and the condition of the enamel after debonding are extremely important to our patients. When an orthodontist in my area passed away, I received a flood of cases that were bonded using a traditional protocol. When viewed microscopically, it became apparent that the removal of flash had sometimes created a microscopic ledge around the periphery of the bracket and in the enamel.

While not obvious to the naked eye, these small ledges created with a fine scaler can ultimately cause decalcification during treatment (Figure 3). This “white halo” effect can compromise the final aesthetics of the smile, and can cause a patient to leave the chair unhappy with the result.

Since incorporating the APC Flash-Free Adhesive System, my office has not documented any decalcifications, even on patients who have had significant gingival inflammation toward the end of their treatment, likely due to poor dental hygiene (Figure 4). Clinically, I have noticed that there are significantly fewer white spots on the teeth with this system.

Figure 3: Removal of flash with a fine scalar can leave ledges underneath the bracket, resulting in potential decalcification.

Gaining Time in the Day

With this simplified process, our bonding time has been reduced significantly. When my practice started using the new system, we tracked our results and on average we went from blocking 90 minutes in our schedule to 70 minutes for a bonding appointment. This includes everything from upper to lower, seven-to-seven, ?28 brackets, and giving post-appointment instructions.

To paint a picture of the time savings that I’m able to realize, ?2 days a week I do three full bonds and 2 days a week I do four full bonds, so I pick up between ?60 and 80 minutes on my schedule per day. I use this time to see more patients, interact with my staff, and focus on practice growth. I am actually able to extend my workday without increasing the number of hours that I am working and paying staff.

I have found that this new technology creates a more efficient office environment and a more comfortable experience for our patients. When patients come in, most of them are anxious, so the faster we can get them in and out of the chair the more comfortable they will be.

Figure 4: Here the APC Flash-Free Adhesive forms a meniscus on the tooth to protect it from decalcification.

Debonding Takes Little Effort

What I didn’t necessarily expect with this new process is an improved debonding process, something that many of our young patients appreciate. When debonding, I am able to use a slow-speed handpiece instead of the fast-speed handpiece we previously used to remove remaining adhesive on the tooth—it takes the same amount of time (Figure 5).

Being able to use a slow-speed handpiece is less abrasive to the teeth and means there is less cold air to irritate the gingiva and give the perception that the debonding process is actually painful to the patient. With very little effort or force, the mesh turns into a powder.

Looking at the Real Cost

I have had orthodontists come to me with concerns regarding paying a bit more for an advanced product or system. I always ask to see if they are tracking their results and bond failure rates. Although a product like APC Flash-Free Adhesive may come at a slightly higher price per unit, that doesn’t mean it’s more expensive. A practitioner considering a switch has to start by knowing what their baseline numbers are, including bond failure rate, the average time spent at the chair bonding brackets, cleaning up flash, and seeing emergency patients or taking care of a debond.

Figure 5: When debonding with APC Flash-Free Adhesive Coated Brackets, some orthodontists can use a slow-speed handpiece to easily remove excess adhesive and increase patient comfort.

Once you know your baselines and see the numbers, it’s possible to put dollar amounts toward the time you would be saving with a more efficient process. For my practice, switching materials has proven to be more cost-effective, and our numbers reinforce it.

We have tracked our bond failure rate since using 460 APC Flash-Free Adhesive coated brackets, and of those, only five brackets had debonded. This translates to a bond failure rate of 1%. (This could possibly be lower than anything that has ever been documented.) An average bond failure rate is 5%. A lower failure rate automatically means fewer emergency visits, and less wasted time and money.

Hygiene Factor

Another aspect of traditional bonding that has some inherent issues is the idea that the brackets are not hygienically sealed. You are taking your gloved finger and pushing the cement onto the mesh of the bracket. Just by doing that, you have introduced oils and other contaminants onto the cement, which could contribute to weaker bond strength

With a system like this, the brackets have never been touched or exposed to any contaminants. The blisters are opened seconds before application, making it a much more hygienic process. Additionally, the brackets are individually packaged and marked, which saves time and potential error (Figure 6).

Bettering Your Practice

While it may not always feel comfortable to explore and adopt new products and processes, it can go a long way in improving overall patient experience and creating a more efficient working environment. With a switch to a new and different bracket and adhesive system, my office has been able to do both of these. I have received many patient referrals due to the ease of the process, and in return, I have been able to take on these patients with the extra time I have acquired. OP

Visit Orthodontic Products’ interactive edition to read more about Internet marketing, social media, and search engine optimization.