Summary: Dentsply Sirona’s Primeprint Model C advanced material offers enhanced safety, free from BPA and other compounds, while integrating with DS Core and inLab CAM software for streamlined workflows and improved clinical efficiency.

Key Takeaways:

- Primeprint Model C reduces printing times and active working time, enhancing efficiency for dental practices and labs.

- Free from BPA and other potentially harmful compounds, it aligns speed, safety, and versatility for a more streamlined, patient-centric additive manufacturing process.

Dentsply Sirona announced the launch of Primeprint Model C, a faster and more versatile 3D printing model material within the Primeprint portfolio.

Improved Speed and Versatility

Primeprint Model C is an advanced material that can be used for thermoforming, working and situation models. It offers improved speed and versatility, enabling dental professionals to complete the full printing and post-processing workflow in one hour, according to the company. In addition to performance, Primeprint Model C is designed with safety in mind. The material is free of BPA, MMA, THF-MA and TPO, reducing risks in its uncured state.

Dentsply Sirona enables a streamlined additive manufacturing workflow. The process starts with a scan, either with Primescan, Primescan 2 or a third-party scanner. From there, dental professionals have the flexibility to design their own appliances using CEREC or inLab CAD Software, order designs from DS Core Create, or utilize their preferred dental lab.

READ MORE: Dentsply Sirona Primeprint Splint Resins Available for Retainers

Integration with DS Core and inLab CAM

With the latest inLab CAM Software Version, called inLab CAM connected with DS Core and the manufacturing features on DS Core, print jobs can be started anywhere from DS Core. DS Core, Dentsply Sirona’s cloud-based platform, is designed to support dental practices and labs throughout their daily workflows, providing a range of tools that enhance efficiency, productivity, and growth. inLab CAM connected with DS Core comes with manufacturing features, allowing centralized management of manufacturing jobs and equipment in one place. This is designed to streamline the production process, improves equipment management, and simplifies documentation with automated reports.

Primeprint Model C furthers this efficient transfer of information and workflow by enabling dental professionals to print working models with less than 30 seconds of active working time during printing and post-processing, according to the company.

“With Primeprint Model C, we are raising the bar for 3D printing materials, offering a combination of speed, safety, and versatility that benefits both dental professionals and their patients,” said Max Milz, group vice president connected technology solutions at Dentsply Sirona.

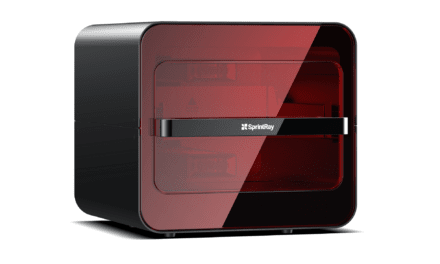

Photo courtesy of Dentsply Sirona