by Michael C. Alpern, DDS, MS

Ligatureless brackets and square biomechanics make treatment easier and more accurate

Ten years ago, I labeled my concept of orthodontic treatment the Fixed/Functional/Splint System. “Fixed” refers to the brackets, bands, and wires. “Functional” refers to the ability of the rapid palatal expansion bite-plane system and bonded flowable composite to allow functional improvement. Finally, splints are involved because the concept permitted vertical unloading of the condyles, protecting the TMJ during cusp-fossa corrections.

The reasoning for this concept included a number of factors.

1) The flat bite-planes of the bonded expander efficiently unloaded cuspids and incisors vertically. Molars and bicuspids received only pinpoint vertical contact. The occlusion was unlocked. “The gate to the corral was opened, and the puppies were free to move,” observed one clinician.

2) The secured bonded expander served as “disposable anchorage,” uprighting and expanding the mandibular arch.

3) Many patients reported significant increases in ease of swallowing and the ability to breathe through their nose. This effectively changed and stabilized the total oral environment. All this happened over the course of less than 5 months.

Following atraumatic removal of the maxillary expander, maxillary bonded brackets were placed on all teeth except the first molars. The previously sized and adapted maxillary molar bands were bonded in place, and a palatal bar system was placed to further preserve maxillary expansion and begin molar torque, rotation, and distalization if required.

Additional flowable, light-cured composite was added to the mandibular molars to continue TMJ and occlusal vertical unloading, vertical control, and functional appliance therapy where indicated.

Changing Wires

The primary method of archwires moving teeth has undergone a significant improvement. In the past 2 decades, major innovations have occurred in archwire metallurgy. Multiple types of NiTi1,2 and Beta Ti wires have been introduced and have proven successful.

With a few exceptions, the method of securing these new archwires to the brackets had just begun to change. The traditional method of stainless steel ligatures has endured because these ligatures securely hold the archwire into the programmed bracket slot without discoloration or force loss. Elastomeric ligatures made application easier and provided increased patient comfort, but most lacked long-term traction and completely lost their effectiveness after 4–6 weeks. Elastic fatigue and discoloration still remains a concern today.

The requirement for an early treatment full-size archwire was successfully met with the introduction of the superelastic, biologically correct force NiTi wires. These wires apply a near-constant force of about 90 g–100 g to central incisors; about 150 g of force is at the cuspids, and about 300 g is at the molars, regardless of the size of the wire. In a traditional .018-in slot, this innovation permits the orthodontist to use a .018 in x .025 wire as the initial wire in most cases. The torque control applied by this wire to the slot effectively prevents molars and bicuspids from tipping, instead creating uprighting with bodily movement. The most notable orthodontic result of this process is very rapid, comfortable, and biologic orthodontic resolution in the mandibular arch.

The Problem With Existing Ligatures

Most importantly, the contact points where each ligature mesially and distally crosses the archwire presents a significant binding point, restraining sliding mechanics. A paradox is obvious. The orthodontist needs enough friction and force to retain the archwire seated in the bracket slot base and yet still maintain control. This same force is a potentially binding limit to sliding mechanics, potentially lengthening treatment and requiring the use of more archwires and ligatures.

Interactive Full-Slot NiTi Wire With a Self-Ligating Bracket

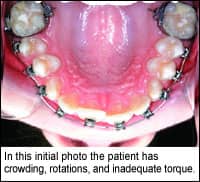

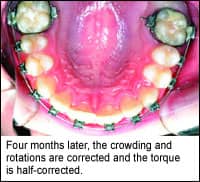

|

|

|

|

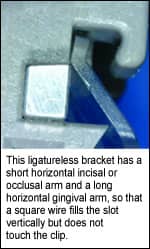

Careful examination of the self-ligating .018-in bracket slot reveals that the gingival, horizontal arm is .0185 in long, while the incisal horizontal slot is .0255 in long. The vertical (tooth surface) wall is .0185 in tall.

The answer for me was to use a .018-in x .018-in superelastic, biologically correct force NiTi wire (or as a minimum, an .016-in x .016-in wire) as my initial wire. This resolved nearly all of my previously encountered control problems with other ligature-free systems.

The uniqueness of the .018-in x .018-in superelastic, biologically correct force NiTi wire in the self-ligating bracket slot is groundbreaking. The .018-in x .018-in wire fills the slot vertically, ensuring complete prescribed movement, including tipping, torquing, and in/out adjustments. Never before has orthodontics had available a wire that realized complete 3-D control, yet was passive when the occlusion was ideally corrected. The interactive clip acts as guide, with the slot-blocker and the finger springs poised to gently correct the slightest movement away from the prescribed activations. The archwire, with the tooth properly aligned, lies passively in the base of the slot, providing the utmost in patient comfort and precise control.

Thus, the .018-in x .018-in archwire resides comfortably in the bracket slot, with minimal activation force, because the closing clip does not contact the wire unless the tooth moves slightly out of position. Only when the tooth position is not identical with the prescription requirements of the bracket slot does it activate gentle, corrective pressure from the spring clip. This provides a new dimension to straight wire appliances called interactivity. If a slight rotation occurs, the mesial or distal “finger spring” will correct the wire to passivity. If torque pulls the wire outward, the spring and slot-blocker will bring it back into alignment.

Not only are the slots aligned when properly finished, but also the wire is straight and passive. This system will indicate earlier in treatment that brackets are misplaced; this can then be corrected without dropping the size of the archwire. This advanced system should also provide more stable finishes as well.

Understanding Interactive Archwire

|

Superelastic, biologically correct force NiTi wire may be hard for a veteran orthodontist to understand—it certainly violates many of my training assumptions. It is completely superelastic, so the forces at any point remain near constant.

Continuing the work of Jarabak3 on the resistance of roots in an arch, Miura, his former student, found that a single wire can be set so that the incisors receive 90 g–120 g of force, the cuspids receive about 150 g of force, and molars are activated with 350 g of force—all in the same wire, regardless of the size of the wire. Again, within the normal range of orthodontic activations, these forces stay near-constant at these points.

This wire can also be obtained with a special ionizing surface treatment. The wire is subjected to a unique ion implantation process, which produces a very smooth, slick surface, minimizing resistance. Further, the surface is changed to titanium nitride from nickel titanium, eliminating nickel from the surface. This process also virtually eliminates breakage, which is a problem with other NiTi archwires, especially when used in early treatment with more highly malposed teeth. I’ve used this wire for several years with conventional brackets and the results were always impressive—rapid tooth movement with minimal patient discomfort. Combining this wire innovation with ligatureless brackets has produced treatment results that delighted patients and satisfied the entire orthodontic team.

Evolution of a “Square Wire” Concept of Biomechanics

Common thought is that a round wire minimizes friction and is nearly perfect for sliding mechanics such as expansion or extraction/space closure. Round wire has deficiencies in control, with minimum torque being most notable.

Rectangular wires are conceived as very good for tipping, torquing, and in-and-out control. Rectangular wire has the deficiency that it maximizes friction to achieve the aforementioned 3-D control.

A square wire is essentially a round wire with corners. Square .018-in x .018-in wires placed in the .018-in-slotted, self-ligating bracket have the advantages of both the round and rectangular wires without the deficiencies. With minimal friction, square wires permit 3-D control. Thus, the orthodontist has the potential for tipping, torquing, and in and out tooth control, while achieving rapid tooth movement because the friction is minimized.

Tom Peters’ most recent book, Re-Imagine, states that to truly be successful, companies must sometimes use “disruptive” concepts to progress and achieve success. Thus, my current archwire technique uses nearly all square wires. I open and close spaces with full vertically filling square wires. The results speak for themselves.

This concept has also helped me finish the remainder of my steel-ligature-tied bracket cases. To finish more quickly and with better results, I have been removing the rectangular wires from my previous technique and replacing them with .018-in x .018-in beta titanium and stainless steel wires.

Where is it written that we must treat orthodontic patients with round and then rectangular wires? Where is the thought process that says that we cannot finish patients in square wires?

Conclusion

So, why did I switch from single-wing to self-ligating brackets using primarily square vertically slot-filling wires as a critical component of the Fixed/Functional/Splint System?

1) It saves valuable chairtime. Archwire changes take 2–5 minutes;

2) Treatment time is markedly shortened;

3) There are significant increases in patient comfort and tissue health;

4) I have 3-D control from Day 1;

5) The spring clips open and close easily, and stay closed;

6) The greater interbracket area maximizes the effectiveness of high-tech wires;

7) I get increased patient cooperation and better hygiene;

8) There is greater patient acceptance due to aesthetics;

9) I have higher staff satisfaction and retention due to less stress; and

10) The results are increasing my number of referrals and starts.

After seeing what self-ligating brackets and superelastic, biologically correct force NiTi archwires have done to my practice, and then seeing my previous patients with binding stainless steel ties, the different shapes of the twins and single-wings, I realize that the self-ligating system, with the Fixed/Functional/Splint effect, is a win-win-win for patients, staff, and the practice. I can only imagine the efficiency when my entire patent load is totally transitioned into this hyperefficient technique. Self-ligating brackets, square NiTi, Beta Titanium wire, and the Fixed/Functional/Splint System have advanced the orthodontic evolution of my practice, and I’m sure you’ll see the same change for the better if you incorporate this exciting new approach into yours.

Michael C. Alpern, DDS, MS, is an adjunct professor of orthodontics at the University of Louisville School of Dentistry. He is a diplomate of the American Board of Orthodontics and member of the Angle Society. He is the author of the OrthoEvolution: The Science and Principles Behind Fixed/Functional/Splint Orthodontics. He lectures internationally and maintains a private practice in Port Charlotte, Fla. He can be reached at [email protected].

References

1. Miura F, Mogi M, Okamoto Y. New appliance of superelastic nickel titanium wire. J Clin Orthod. 1990;24(9):544-548.

2. Miura F, Mogi M, Ohura Y, Hamanaka H. The super-elastic property of the Japanese NiTi alloy wire for use in orthodontics. Am J Orthod Dentofacial Orthop. 1986;90(1):1-10.

3. Fizzell, JA, Jarabak JR. Technique and treatment with the light-wire appliances. St Louis: C.V. Mosby, 1963.