David D. Richter, DDS, MS, a 25-year veteran of the profession, finds what all orthodontists seek in taking a risk on the latest technology: More efficient treatment time and better results with the latest custom bracket system

By Greg Thompson | Photography by Tracy Edgar

It may sound like a cliché, but David D. Richter, DDS, MS, got into the orthodontic profession as a way to impact people’s lives. While earning his dental degree at the University of Washington, Richter saw the latest technology as a means to that end and has kept a keen eye out for the latest innovations ever since.

After additional studies at the University of Oklahoma produced an orthodontic certificate and a master’s degree, he returned to Colorado where he grew up, eventually settling in Greeley, a city of about 90,000 residents in the northern part of the state. Practicing there for 20 of his 25-year career has led to deep roots within the community and a thriving practice that has indeed impacted hundreds of lives for the better.

Just a 4-minute drive from home, the venerable 3,700-sq-ft Richter Orthodontics building houses a trove of high technology equipment designed to improve patient care and boost outcomes. “Most orthodontists use brackets that were designed in the 1980s,” says Richter, “back when the rotary telephone was in use.”

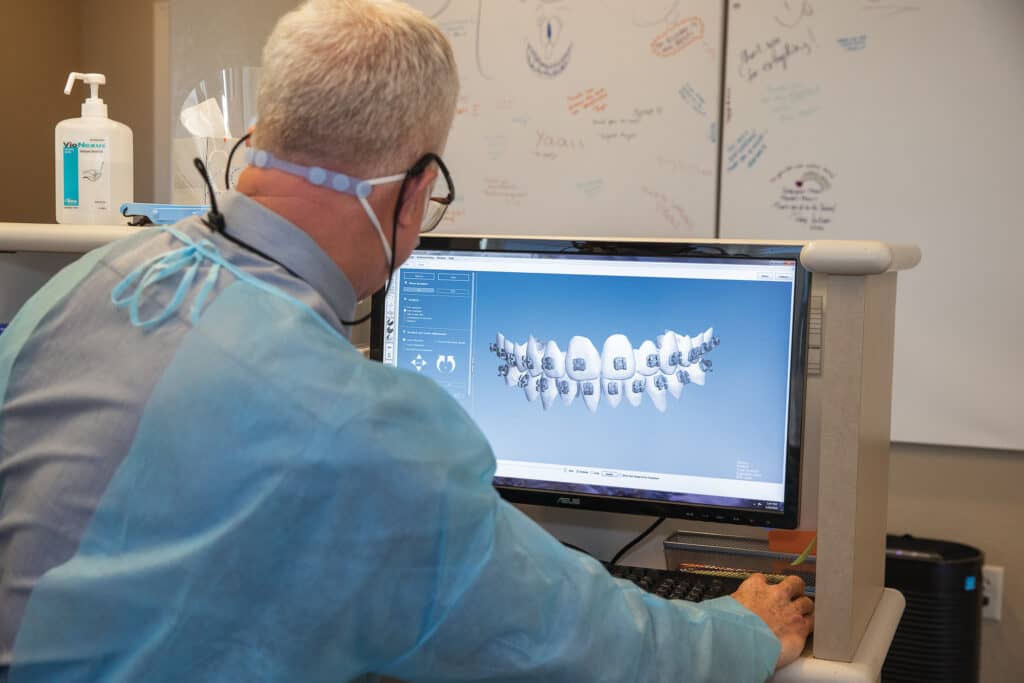

Always seeking to break out of that low-tech trap, Richter recently added the KLOwen Custom System to his technology mix, a treatment that combines digital workflow with an innovative patented bracket prescription. As detailed in Orthodontic Products and elsewhere, the customization in the KLOwen system relies on treatment planning software which provides accurate bracket positioning and 3D-printed IDB trays.

Digital Workflow for Custom Braces Treatment

Once patients are scanned, the software automatically chooses the “perfect” bracket for each tooth from the company’s “LEGO” kit of 27 19.5-inch slot brackets and tubes of various thickness and torques. Using 3D-printed IDB (indirect bonding) trays, brackets are bonded according to the software’s custom prescription. According to Richter, placement of the brackets allows the wires to more completely express, reducing the need for wire bending and bracket repositioning resulting in reduced chair and overall treatment time.

“I’m definitely an early adopter,” Richter says. “That philosophy enables me to bring technology to my staff and to my patients and provide that cutting edge technology. When it works well, as it does with KLOwen, treatment is more efficient. Being involved in that process is what really gets me charged up.”

Much of Richter’s current enthusiasm for treating patients using custom braces derives from the precise bracket positioning made possible by KLOwen. In the past, that lack of precision led to treatment setbacks even for the most diligent practitioners. “In a perfect world, we could see exactly where we want to be and where the roots need to be,” Richter explains. “Even though I’ve positioned brackets for a long time, 6 to 9 months into treatment we will check to see if the roots are parallel, or clinically if the brackets are not in a good position. If necessary, we’ll reposition those brackets and go through that wire sequence again.”

To overcome that problem, bracket positioning within the KLOwen System uses IDB, a familiar method that’s been around about 3 decades. There are occasionally concerns with IDB and KLOwen specifically seeks to address those challenges.

“All the IDB trays I’ve ever used have been too soft, and when we go to place them onto the teeth, there is a lot of room for error,” Richter explains. “It’s very technique sensitive. If we don’t get that one step correct, we’re going to have to reposition the brackets later. The KLOwen IDB tray is a little more rigid. When you put it on, you know when you’re home.

“It is not as technique sensitive,” he continues. “When you seat these on, you know they’re seated properly—and then we cure the brackets. We have a very accurate IDB system, so the brackets are exactly where they need to be.”

Another differentiator within the system concerns slot size. As most orthodontists know, the wire is smaller than the slot size, to the point where there is up to 30 degrees of play. The most popular slot size in the US is .022, and most orthodontists will finish at .019 wire vertical height. Richter uses the analogy of a car that drifts to the left, requiring the steering wheel be turned to the right.

“It’s the same concept,” he says, “because the wire does not fill the slot completely. With the KLOwen system, the wire almost completely fills the slot to where there’s only 5 degrees of play. We have extremely accurate bracket placement and we have a system where the slot is almost completely filled, so the expression of the prescription of the bracket is almost completely expressed to the position of the tooth.”

The result is a treatment route that goes from “point A to point B in a straight line as opposed to going from point A to point B in kind of a zig zag line.” That means measurably shorter treatment durations, borne out in Richter’s office by 25% to 30% reductions in treatment time.

Early Adopter Mentality Leads to Enhanced Doctor-Patient Experience

Yet another benefit is doctor time. Brandon Owen, DDS, MS, founder and president of KLOwen, specifically wanted to create a system that streamlines the doctor experience. “I want to take [doctor labor] down to 15 minutes per case,” Owen told Orthodontic Products in an interview last year. “Just wire one, wire two, wire three, and once you get that heaviest wire in, now all you’re doing is babysitting elastics—and that you can do remotely with Grin and SmileSnap. If we can go from 20 visits to less than seven visits to the orthodontist with a better result, that’s a huge value proposition for our specialty.”

“If we train our assistants to do this correctly, they can place the brackets, cure them, and then I come back and check,” Richter confirms. “My doctor time is about 2 or 3 minutes. I can verify that bracket position on the tooth with the virtual image on the website, and it shows me exactly where that bracket is. I can verify it was done correctly. It’s amazing.”

Richter admits that some gadgets (that will remain nameless) throughout the years failed miserably, costing time and money. He knows the early-adopter philosophy carries some risk, but the potential upside for better patient care makes it worthwhile.

Unlike some other innovations throughout the years, Richter was able to match the technology with a face when he met Owen in a study group a few years ago. With the founder himself presenting the concept, Richter was able to grasp the KLOwen method from the start, remarking that, “I could see the real value of what he was talking about. It made a lot of sense right from the beginning, and we started a few cases to get a feel for it, and then eventually we jumped all in.”

In the future, KLOwen hopes to offer ceramic and self-ligating options as well. An additional software update will automate the in-office process, giving assistants the power to scan and load data, then click a button that will auto-segment the teeth and perform landmark identification—creating an ABO setup for the patient in minutes. Once the doctor reviews and tweaks the setup, it can then be sent straight to the 3D printer for the IDB tray to print. In October 2020, the KLOwen system was used to do 4 same-day custom braces starts with 2 to 4 hours turnaround, a feat Owen has been working on for years.

Expanding the Practice

While the flagship practice has naturally faced challenges due to the global pandemic, Richter is optimistic. Three months ago he hired a new associate, and in January 2021 he broke ground on a new 6,700-sq-ft building. The in-progress edifice—also in Greeley—will provide a rare opportunity to build a state-of-the-art facility from scratch while expanding the patient base.

Most people in that base seek out Richter for cosmetic reasons, but he makes a point to educate prospective patients about the value of a bite that not only looks great, but functions well, lasts a long time, and contributes to better overall health.

“Outside of the office, we also do a charity run for suicide prevention,” Richter says. “The first year we raised $13,000. Last year it was $25,000. We still raised $10,000 this year even though it was virtual. So, we’re really involved in the community, and that goes back to my mission statement which is to give back. My main purpose is to cultivate something that can be a helping factor in our community, and we work on that a lot.”

Factor in active continuing education and it all adds up to a full-speed-ahead commitment to the profession—fueled by enthusiasm, purpose, and technology. Plans for another associate are in the works for the new practice, which is expected to be finished by the end of this summer.

By that time, much of the United States may indeed be vaccinated against COVID-19, and perhaps more of those luminous smiles cultivated by orthodontists will be visible. Like so many people over the last 10 months, Richter has lived behind his mask searching for a work-flow that maximizes results.

After placing initial wires, he typically goes 8 to 12 weeks. After that, it’s 6 to 8. As a result, when a 5-week pandemic-related shutdown happened last year, progress was not overly affected. “We weren’t able to start patients obviously during that time, but we maintained our efficiency,” Richter says. “We’re also seeing a lot higher conversion rate with these [KLOwen] because they are custom. We typically see our patients for 20-plus visits, and we’re able to see them in as few as 10 or less visits because of the efficiency of the system. We don’t have to change our price point compared to regular braces. We don’t have to up charge them.”

When and if things get back to pre-pandemic conditions, Richter anticipates that some virtual/telehealth workflow changes will stick. For example, instead of patients coming in for an annual observation appointment, Richter and staff members can perform teleorthodontic examinations to determine what is needed.

Richter adds: “If we have patients who are supposed to come in after 6 or 8 weeks, and we do telehealth, we can see if the rotation is out of the tooth. If it’s not, they are not going to be ready for the next wire, so we’ll say, ‘Wait to come in.’ It’s really made it a lot more efficient. We’re saving those people a lot of time driving. If we’re going from 20 appointments for the entire treatment, and they’re going down to 10, and they have a 2-hour drive (not unusual for Richter’s patients), we’re saving them about 40 hours of driving.”

Fewer hours with the same (or better) results has long been the holy grail for orthodontists and patients alike, and each year it gets better. For Richter, it means a bit more time to take advantage of the Colorado lifestyle with activities such as skiing and wakeboarding. Three grown sons, plus a 2-year-old son, all keep the orthodontic veteran on his toes.

It’s a lot to handle, but Richter also finds time for new inventions that allow him to contribute to the technological world that has helped him throughout his career. “I have a patent on a virtual articulator, and I also have a patent of a retainer,” he muses. “It’s called the Richter retainer and it’s a cross between the Hawley traditional wire retainer and the clear retainers. It’s true I have a lot going on, but I feel like I’m just getting started.” OP

Greg Thompson is a freelance writer for Orthodontic Products.