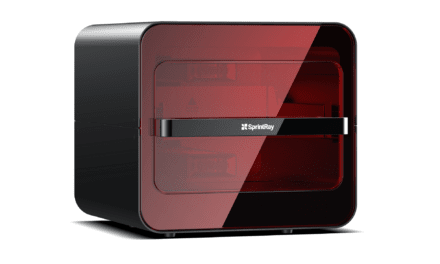

Desktop Health announced the availability of the Einstein Pro XL 3D printer featuring DLP technology to improve speed and accuracy.

Desktop Health announced the global availability of the Einstein Pro XL, a high-accuracy, high-throughput 3D printer for dental labs, orthodontists, and other medical device manufacturers.

The Einstein Pro XL is a DLP-based polymer printing system that uses a 4K ultra-high-definition projector to deliver precision printing of 45 microns in X and Y across a large build area of 9.8 x 5.5 x 6.5 in (249.1 x 140.1 x 165.1 mm).

The high-speed printer features proprietary Hyperprint technology that reduces print times with strategically applied heat and a closed-loop sensing system, in addition to other enhancements.

The Einstein Pro XL joins the entry-level Einstein desktop printer launched in 2022 as a complete set of printers for dental and medical professionals.

“The Einstein Pro XL stands alone as a premium, production-grade DLP system in the sub-$40,000 dental lab market,” said Ric Fulop, founder and chief executive officer of Desktop Metal. “Built on a trusted DLP architecture, the Einstein Pro XL is loaded with upgrades that make it an ROI powerhouse for productivity-oriented labs serving the most demanding dental professionals and patients.

It can 3D print a wide range of resins for dental models and other devices such as bite guards. It can also print the company’s proprietary Flexcera material for strong temporary and permanent restorations.

The Einstein Pro XL is a DLP printing system, a form of 3D printing photopolymers that originated in 2002 with the EnvisionTEC Perfactory series, the base platform for the Einstein Pro XL.

DLP offers speed and quality, using a high-definition projector to rapidly flash and cure one layer of resin at a time using a theater-quality DLP chip. Because projectors expose light in pixels, the brightness of each pixel can be controlled individually. That allows for curing each pixel to different depths or volumetric pixels, also known as voxels.

Controlling each voxel improves the accuracy and surface quality of 3D printed parts, especially when paired with custom optics and specific light wavelengths.

It features a 4K UHD projector powered by an industrial DLP chip below the print vat. Dual linear slides for the moving build plate ensure a high-accuracy print across the entire print bed by maintaining a parallel build environment. Depending on the material being processed, layer thicknesses down to 25 microns can be achieved.

Photo courtesy of Desktop Health