The rapid palatal expander (RPE) is the most commonly prescribed orthodontic laboratory appliance. A standard RPE is composed of two primary components: the framework and jackscrew. The framework secures the appliance to the teeth, tissue, palatal bone, or a combination thereof, while the jackscrew provides the activation for rapid expansion. Though orthodontists are familiar with the various popular types of RPE frameworks (ie, Haas, Hyrax, Bonded, and MARPE), the jackscrew remains poorly understood.

This article reviews the components of the standard linear jackscrew in order to improve clinical efficacy with the RPE. The chemical elements that constitute it will also be discussed.

Historical Perspective

The patient was provided with a key and simply instructed to turn the jackscrew to keep the pressure uniformly tight. After 2 weeks, she returned to the office with her crossbite corrected and her arch widened by a quarter of an inch. More significantly, Angell observed the presence of a median diastema and concluded that the maxillary bones had separated.

Unfortunately, his theory of sutural separation was rejected by the Dental Cosmos board. Angell was censured by the established dentists and anatomists of that time, which resulted in a clinical moratorium for the jackscrew expander.2 The appliance was used only sparingly in the United States up to 1930, after which, there was almost a complete abandonment of the rapid palatal expansion technique.3

The jackscrew expander reemerged in the 1960s with Haas.3-5 The Haas RPE (1956) featured a modern jackscrew, made by Dentaurum, with a tooth- and tissue-borne framework. As rapid palatal expansion became routine, other frameworks were introduced, such as the Hyrax (1968), Bonded (1973), and MARPE (2004) expanders, but the general components of the modern jackscrew remained the same.

Components of the Jackscrew

Components of the Jackscrew

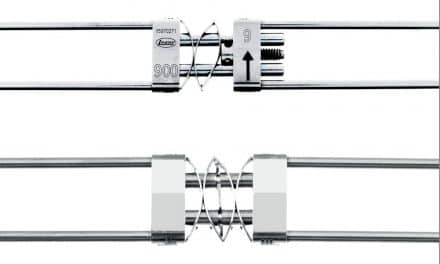

The standard jackscrew consists of four primary components: (1) a perforated cylinder, (2) a leadscrew, (3) guide pins, and (4) the platform (Figure 2).

Perforated Cylinder

The perforated cylinder, seated around the leadscrew, is turned to provide expansion. The cylinder has four holes, so each key turn is a quarter turn of the cylinder. For the majority of jackscrews, each turn equals 0.2 mm of expansion. Therefore, one full-cycle, or four turns, equals 0.8 mm of expansion. Many orthodontists were incorrectly taught that four turns equal 1.0 mm of expansion.

Leadscrew

The length of the leadscrew determines the maximum amount of expansion. Jackscrews can range between 3 and 18 mm of maximum expansion. For banded or bonded RPEs, the typical jackscrew achieves 10 mm of maximum expansion. Removable expanders have smaller jackscrews that achieve less expansion, usually 3 to 7 mm.

The guide pins sit above and below the leadscrew to provide support. The first-generation modern jackscrews did not have a guidance mechanism to secure the appliance against torsion. A standard four-leg RPE uses two guide pins. Conversely, a two-leg RPE requires only one guide pin. These monoguided jackscrews are also known as mini-jackscrews, because they have a smaller platform (Figure 3).

Platform

The platform contains the leadscrew and guide pins, and connects them to the framework. Its surface is labeled with two identifiers: a small arrow and a number. The arrow indicates the direction of turning (opening) with the key. The number, referred to as the nominal size, indicates the approximate amount of maximum expansion in millimeters.

Understanding these components can help determine the maximum allowable turns of the jackscrew. For example, a jackscrew with a nominal size of 10 can achieve approximately 10 mm of expansion in 50 turns (Figure 4). After 53 turns, the leadscrew and guide pins will disengage from the platform. The jackscrew can be expanded further, however, if the platform is extended medially with acrylic (Figure 5).6

Nevertheless, most orthodontists only prescribe the customary 30 turns of the jackscrew in patients with moderate to severe crowding. But is this amount of expansion adequate? Thirty turns provides 6 mm of arch width, which equates to 4.2 mm of arch perimeter (ratio of arch perimeter to arch width = 0.7)7—less than the width of a mandibular incisor. Therefore, a majority of patients would likely benefit from more turns of the jackscrew.

Composition

The jackscrew is made of a stainless-steel alloy. The three largest chemical components are iron (50% to 80%), chromium (13% to 23%), and nickel (3% to 15%). Nickel, the most common contact allergen, is of greatest concern to patients. Still, only a single case report of a nickel allergy associated with a RPE could be found in the literature, and the allergic reaction was likely caused by the band and not the jackscrew.8

For patients with nickel-allergies, most laboratories carry nickel-free, titanium jackscrews (ie, Titan-hyrax, from Dentaurum; and Forestadent titanium, from Forestadent), but the RPE framework would have to be a Bonded expander as there are currently no nickel-free bands.

Conclusion

The standard linear jackscrew is composed of a perforated cylinder, a leadscrew, one or two guide pins, and a platform that is labeled with the nominal size and direction of turning. Each key turn of the perforated cylinder generates 0.2 mm of expansion. The most common jackscrew provides 10 mm of expansion. The chemical composition of a jackscrew is a stainless-steel alloy, which includes nickel. OP

[sidebar float=”center” width=”500″]

Jackscrew in Action

Reactivation of an expander after maximum expansion.

A) Phase I Haas expander after maximum expansion. The expander has a nominal size of 8. The panoramic radiograph indicated that more expansion was needed to correct the patient’s ectopic canines.

B) Applying Triad gel to extend the platform of the expander. Careful attention is given not to cover the perforated cylinder. The Triad gel prevents the leadscrew and guide pins from disengaging the platform.

C) The Triad gel is cured and the patient is now ready to receive further expansion. The jackscrew still turns with ease.

[/sidebar]

References

1. Angell EH. Treatment of irregularity of the permanent or adult teeth. Dental Cosmos. 1860;1:540-544, 599-600.

2. Timms DJ. The dawn of rapid maxillary expansion. Angle Orthod. 1999;69:247-50.

3. Haas AJ. Rapid expansion of the maxillary dental arch and nasal cavity by opening the mid-palatal suture. Angle Orthod. 1961;31:73–90.

4. Haas AJ. The treatment of maxillary deficiency by opening the mid-palatal suture. Angle Orthod. 1965;65:200–217.

5. Haas AJ. Palatal expansion: just the beginning of dentofacial orthopedics. Am J Orthod. 1970;57:219-255.

6. De Mendonça MR, Pereira AL, Fabre AF, Busato MC, Cuoghi OA. Immediate reactivation of a modified Haas expander after full screw expansion. J Clin Orthod. 2008;42:43-8.

7. Adkins MD, Nanda RS, Currier GF. Arch perimeter changes on rapid palatal expansion. Am J Orthod Dentofacial Orthop. 1990;97:194-9.

8. Counts AL, Miller MA, Khakhria ML, Strange S. Nickel allergy associated with a transpalatal arch appliance. J Orofac Orthop. 2002;63:509-15.