With the launch of his PSL bracket and wire system, the Norris 20/26 from DynaFlex, Texas-based orthodontist Robert “Tito” Norris, DDS, finally found a solution to a question posed during his residency

By Alison Werner | Photography by Michele Papp

Robert “Tito” Norris, DDS, has been tinkering since he was a kid hanging out in the lab of his father’s optometry practice. When he got to college, he assumed a major in mechanical engineering would channel his curiosity and inventor’s spirit. His grades were good, but the pull wasn’t there. And then he had an aha moment common to many inventors.

While an undergrad, Norris, who had always wanted braces, finally had a job and the dental insurance that went along with it. As his treatment progressed, the epiphany came. He saw how orthodontics was, as he put it, “like engineering but in the mouth.” What’s more, orthodontics allowed you to own your own business and, more importantly for the self-described “social animal,” interact with people.

Back to San Antonio, by Way of Japan

Norris switched his major to biology, minoring in mechanical engineering, and headed to dental school at the University of Texas Health Science Center San Antonio. Upon completion, the Texas native followed his wife to Washington, DC. She had gone through medical school in San Antonio on an Air Force scholarship and was sent to DC to complete her residency. Norris spent that time completing a general practice residency at the VA hospital in DC, and then an orthodontic residency at Howard University. With their residencies complete, Norris’ wife was able to make a wish list of places she’d like to live to pay back her commitment to the Air Force. The couple’s list focused solely on U.S. locations so Norris could take a state board and begin his work as an orthodontist. So of course, she was assigned to Misawa Air Base in Japan. In order to accompany her to Japan, however, Norris had to join the Air Force as well. That’s how he found himself as the chief of orthodontics at the base.

“Which just means I was the only orthodontist there,” Norris says. But the time provided invaluable experience and lessons he could take into private practice in the future.

The patient population at the base in Japan was split between military members with severe orthodontic needs and transfer patients. For an active duty military to qualify for orthodontic treatment, they must require orthognathic surgery or be periodontally compromised. This gave Norris a unique opportunity to scrub in on all his orthognathic surgery cases—something that wouldn’t be possible in a private practice. And with regard to those transfer cases, they were primarily the children of active duty service members who had braces placed in the United States before their parent was stationed in Japan. The experience gave Norris a huge insight into how orthodontists across the country practiced.

“I got to accept a lot of transfer cases from all over the US and quite frankly, most of them were not in very good shape in terms of the mechanics. Bracket positions weren’t good. Hygiene wasn’t good. So, it was a great learning experience for me because I got to see a microcosm of what was going on—the state of the union of orthodontics in the United States. It really inspired me to be better than that. I took it upon myself to set up much higher standards of care for the patients I treated,” he said.

When the couple completed their tour in Japan, they returned to San Antonio, where Norris went into private practice opening Stone Oak Orthodontics in 1998. As San Antonio is home to five military bases, he still sees a significant number of transfer patients and has a policy of never turning a transfer patient away and going the extra mile to help patients who need to transfer when moving away from San Antonio. Often, he turns to the network of friends he has built through various study clubs and speaking engagements to find his patients a new home. Norris also makes a point of ensuring his transfer patients are treated fairly when it comes to the financial cost of orthodontic treatment. “Transfer patients shouldn’t have to carry additional financial burden just because they’re moving and changing doctors. So, we try to always be very, very fair with patients financially as they move to a new office,” he says.

Answering a Question

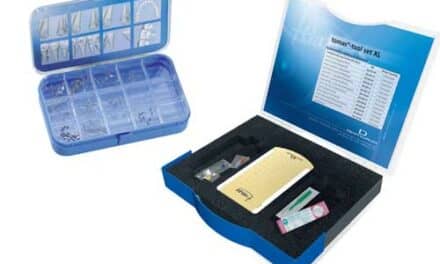

In August, DynaFlex unveiled the new Norris 20/26 passive self-ligating (PSL) bracket and wire system—Norris’ brainchild. The system is the result of Norris’ decades of experience treating patients with the leading passive self-ligating systems and that background in mechanical engineering.

A self-described “thinker and tinkerer,” Norris has spent much of his life trying to fix things or build the better mousetrap. Some ideas—like a heated toilet seat or a coffee mug that maintained the beverage’s temperature—he’d later discover were already on the market; but in the field of orthodontics, he had found his niche.

The idea for what is today the Norris 20/26 PSL bracket and wire system grew out of a question he asked in his residency back in the 1990s: For the last 150 years, we’ve basically been using this one bracket slot system—a .022. Yet the largest wire in the building is an .019—.019 x .025. Why use that? Why don’t we use a bigger wire?

The answer back, of course, was that a .021 wire was too thick and strong. It would burn the roots and lead to root resorption; plus, it would hurt the patient and break the brackets. When Norris pointed out that using the undersized .019 wire meant a loss of rotational and torque control, the reply was “that’s what we have to work with and that’s how it’s always been.”

Norris wasn’t satisfied.

Once out of his residency, Norris went to the major orthodontic suppliers and asked about making the bracket slot slightly smaller to fit the wires. One company with a PSL system already on the market didn’t see the need to invest in retooling its already successful product. Norris eventually found a partner in 2016 in MidAtlantic Ortho (MAO). A year later they released the FiT.20 system, which was rebranded as the FiT20/26 in 2018. The .020 x .026 slot size was designed to provide control throughout the working and finishing phases of treatment—exactly what Norris had envisioned. When MAO was sold to DynaFlex, the latter expressed interest in the 20/26 slot size and was willing to work with Norris on a new bracket system.

Tighter Control

As Norris worked on the design for the new bracket system, he used the opportunity to incorporate feedback from colleagues and his assistants who had worked with the FiT.20. The result: A true twin, PSL appliance. The Norris 20/26 features the best-in-class features orthodontists expect: four true tie-wings with undercuts that can accommodate ligature ties and elastic chain; cobalt-chromium composition for nickel-free use by allergy-sensitive patients; a door mechanism with a rounded leading edge to aid in seating archwires as the door is closed, and “glided” opening and closing; universal bicuspid hooks for reduced inventory; and a mechanical base for trouble-free bonding.

For Norris, the beauty of the Norris 20/26 comes down to the tightened tolerances. Whether you have an .025 wire in an .028 slot or an .019 wire in an .022 slot, you’ve got more slop and play and less control. But when you tighten those tolerances down, you have the control that is key in finishing. “That’s where the rubber really meets the road—those end stages of treatment. And if you look statistically at what causes people to spend more time in treatment and what causes extra appointments during treatment, it’s during finishing. It’s not out of the gate. It’s not the unraveling of the teeth that takes extra appointments. It’s the finishing that takes more appointments because it’s the detail, the control there that has been historically lacking in PSL systems. Those two dimensions are two really important features,” Norris says.

Norris again broke from convention with the Norris Extra Broad archwires he designed to complement the 20/26 bracket. He took what he knew about expanded arches and aesthetic expression to create this extra broad arch form—a reported 30% broader than competitors. With a non-coordinated arch, it’s possible to treat both the upper and lower with the same form. Moreover, this extra broad arch achieves a number of efficiencies and effects. Not only does it afford maximum space as it expresses each tooth to its full outer-most potential, but it also gives teeth a greater range of motion, making leveling and aligning easier. In addition to reducing dark posterior buccal corridors, the rounded corners of the rectangular wires aid in wire seating as the PSL door is being closed.

“After using other broad arch forms, I said, ‘Let’s push it. Let’s go even broader.’ Not that you always achieve everything that you put in there in terms of the extra broad width, because less than 10 grams of lateral force is being applied, but at least it’s going towards that dimension and you can maximize the amount of arch width that your jaw bones can withstand or tolerate,” he says.

As a result of the bracket’s reduced slot size, the extra broad arch forms, and additional control, most cases can be treated with as few as four wires, according to Norris and DynaFlex. And as Norris puts it, the Norris 20/26 is the first bracket and wire system to provide both passive and active self-ligation. “It’s passive in the beginning when you want the freedom and the movement; yet, when you progress to the full-size wire, it becomes an active bracket during working and finishing stages of treatment,” he says.

The Business Side

Norris is a businessman as well as a clinician, which means the Norris 20/26 had to have a positive impact on the bottom line for him to be completely satisfied. To get a handle on how the system performed, his practice recently ran a controlled study, comparing the last 500 cases he finished with the Norris 20/26 system with the previous 500 cases he finished with another leading PSL bracket system on the market. The competitor’s system averaged 19 appointments to finish a case—right in line with the national average. Meanwhile, the Norris 20/26 averaged 14, saving 5 appointments that could go towards starting another patient. Norris and his team are currently working to get the number between 10 and 12.

The fact is the Norris 20/26 is a premium bracket system. It costs more to manufacture and, thus, is more expensive. But Norris looks at that cost against the number of appointments he’s saving. “Just saving one appointment would pay for the difference in the cost of the bracket,” Norris points out. “Your ROI would be enormous if you experience the same difference in appointments. The only thing I changed was the bracket system. I would think that other people would experience similar gains in efficiency if they made a change to this bracket system.”

Influencer

Early in Norris’ career, a mentor said something that stuck. “Tito, when you become an orthodontist, you are going to be an influence on the patients and the parents you serve. It’s going to be your decision as to what type of influence you want to be.” For Norris, that influence translated into a commitment to environmental responsibility, mentorship, and community involvement.

Norris, a former Eagle Scout, grew up with the scouting tenant of stewardship—especially as it relates to the planet. As a small business owner, he committed to making his office completely “green,” starting with solar panels in 2007. Then when the space adjacent to his office became available, he took the opportunity to not only double the size of his practice, but to make it LEED-certified, becoming, in 2010, the first LEED-certified orthodontic office in the world.

LEED (Leadership in Energy and Environmental Design) certification goes beyond solar panels. It is an internationally recognized green building certification system, signifying sustainability achievement and leadership. It provides a third-party verification that a building or community was designed and built using strategies aimed at improving performance across a number of metrics, including energy savings, water efficiency, improved indoor environmental quality, and stewardship of resources and sensitivity to their impacts. For Norris’ office, this translated into a design that, among other things, gave every room access to natural light to achieve energy efficiency, and materials choices like non-VOC paints and carpet made out of recycled fibers.

Norris has also taken “influence” to mean mentorship. Ray Caesar, DDS, joined Norris’ practice 2 years ago, but the two go back much further. Caesar, who grew up in San Antonio, started interning with Norris 12 years ago during his summers home from Duke University where he was an undergrad. Like Norris, Caesar completed dental school at the University of Texas Health Science Center San Antonio and went on to do his orthodontic residency at Howard University. Norris takes pride in their connection and the fact that they are now able to work together as colleagues.

He and Caesar see to a practice that has grown to two locations and a 22-member staff. Every quarter the practice closes so that the entire team can volunteer at a range of organizations, including the Humane Society, Habitat for Humanity, and Wounded Warriors. But more recently, the practice has been focused on what it can do for its community of patients during the COVID-19 pandemic.

Like most orthodontic practices nationwide, Stone Oak Orthodontics shut down for 6 weeks. Norris knew his long-established infection control protocols would keep staff and patients safe once they reopened. However, they did add a few new features to give everyone peace of mind, including hands-free handicapped door openers to allow for touch-free door opening. In addition, they adjusted their scheduling to allot time for cleaning and disinfecting between patients. As is true of many practices right now, the schedule isn’t as efficient as before, but all these efforts translate into something more important.

“This morning I had this poor little girl who hadn’t been out of her home in 4 months, but when she saw all the things that we’d put in place here she was very, very comfortable. She said, ‘Thank you so much for doing what you guys have done’,” Norris shares. OP

Alison Werner is the chief editor of Orthodontic Products.