A digital intraoral scanner is now a vital component of your clinical workflow. So what’s next? According to Todd Ehrler, DDS, MS, a 3D printer.

Ehrler, founder and president of Orchestrate Orthodontic Technologies (Orchestrate 3D), Rialto, Calif, is no neophyte when it comes to 3D printing technology. He first began using the technology in his practice in 2007. By 2012, he had fully integrated 3D printing into his practice workflow. Today his 3D printer is in daily use, printing models for an array of orthodontic appliances such as aligners. As Ehrler sees it, once a practice goes digital on the patient acquisition side, it only makes sense to continue down the digital road. But that doesn’t necessarily mean you have to run out and buy a 3D printer today. Yes, there is an argument to be made for not putting off the purchase, but there are resources out there that allow you to test the waters before you take the plunge.

To those who wonder if the 3D printing technology is ready to meet the needs of orthodontics, Ehrler says yes. The printers on the market today are faster, smaller, and less expensive. And as for materials, Ehrler argues the vast majority meet the needs of orthodontists—with one caveat. Ehrler contends the materials to directly print aligners are not quite there yet. The resins that do have the thickness, resiliency, and clarity orthodontists need are too expensive. “The qualities and the cost are not there yet, but I’m confident it will happen,” he adds.

Ehrler first began using 3D printing technology in his practice in 2007. Photos courtesy of Todd Ehrler, DDS, MS.

So, what should you look at when buying a 3D printer? Well, first take a look at your needs. Look at your patient volume and determine what type of printer you need to meet it. Ehrler says estimate volume on the high side because your patient volume will likely increase. Then, find a vendor who is going to have the knowledge and expertise to help your staff integrate the technology and really utilize it. After all, this isn’t just a cool toy. You want to get the best return on your investment.

“I’ve always thought 3D printers are only expensive if you don’t use them. The ROI for the orthodontist using a 3D printer is enormous just because we can make so many appliances for a fraction of the cost [of outsourcing this step]. But if they’re not using the printer, then they’re not getting the ROI.” It’s as simple as that, says Ehrler.

And it should be staff—the assistants—who are working with the printer, says Ehrler. “There’s a learning curve with it just like there was with intraoral scanning, but it’s just a new skill that needs to be practiced,” he says. “I would say there’s a lot of correlations with taking a regular alginate impression and pouring it up in plaster. The first time you did it, it was awkward because you didn’t know the steps.”

For the practice that makes the plunge and buys a 3D printer, there is tremendous clinical control to be had, says Ehrler. In the case of his aligner-only patients, he has a completely digital workflow that keeps all the steps in-house. “I can scan the patient in my office, then with Orchestrate [treatment planning software], I can move the teeth and create the treatment plan. Then I can print the models and make the aligners.” All of this can be done at a lower cost and, if he wants, in the same day—yes, the patient could have their aligners the same day as the intraoral scan. “In this scenario, I have tremendous clinical control over the process because if the patient is not tracking how I want, then I can just simply rescan them and make them a new aligner within a day if I want to.”

But what if you’re still not ready to buy a 3D printer? There are still ways to incorporate the technology and completely digitize your workflow.

That was actually Ehrler’s motivation for starting Orchestrate 3D. He wanted to create a company that could help orthodontists piece together a digital workflow that works for them. Today Orchestrate 3D offers a spectrum of workflow options.

At one end of the spectrum is the orthodontist who is interested in 3D printing, but doesn’t want to actually buy a 3D printer. This orthodontist has the intraoral scanner and the treatment planning software. In this case, the orthodontist turns to Orchestrate 3D for printing services. These printed models would then be shipped to the practice where the appliances can be made in the office.

“A lot of orthodontists start off that way,” Ehrler says. “They get the intraoral scanning and the software down, and then once they have those things operating efficiently in the office, they will then purchase a 3D printer and just plug that 3D printer into their workflow.”

A staff members removes a finished model from the 3D printer. Photos courtesy of Todd Ehrler, DDS, MS.

At the middle point on the spectrum are the doctors that have 3D printers but don’t want to do the treatment planning. A common scenario is the doctor who likes the convenience of having the 3D printer in-house to make appliances, but is too busy to spend time with the treatment planning software to plan out the case. In this scenario, the orthodontist uploads the patient’s scanned files with a brief prescription to Orchestrate 3D and the company’s lab technicians do the treatment planning. The practice can then print the models and manufacture the appliances in-house.

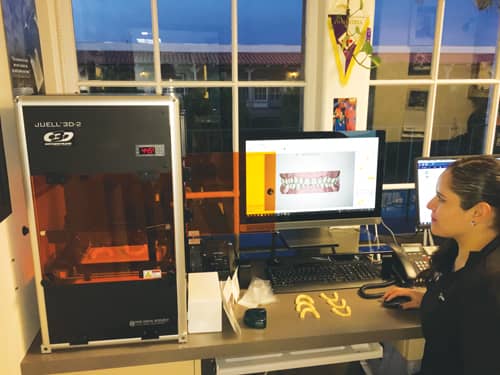

At the other end of the spectrum are those doctors who want to do it all themselves and are ready to buy the equipment to do so. Orchestrate 3D offers the O3D software suite, as well as the Juell O3D-2 printer and resin materials. The O3D Complete package gives orthodontists all the tools to have in-house control over aligner therapy and other treatments.

Ehrler is quick to point out that even if a practice doesn’t own the Orchestrate 3D printer, the company still works to help practices integrate the technology they do have. “I’d say the majority of our doctors don’t have our printer. But we can help them integrate their printer into their office. We’ll walk them through the process regardless of the printer they have,” he says.

Ehrler is confident that every orthodontist who owns an intraoral scanner will eventually own a 3D printer; and more importantly, he contends it will help orthodontists better compete with direct-to-consumer companies. “With 3D printing, you can compete and make aligners at price points the consumer [is comfortable with],” he says.

And if you’re thinking of waiting for printers to get a little less expensive, Ehrler points out that there is a cost to delaying integration. While you wait for that $20,000 printer to drop down to $15,000, consider the increased revenue (lab fee savings, new patient starts) you lose out on by delaying—it likely will be higher than that $5,000 price difference.

So now ask yourself: Is it time to integrate 3D printing into your practice? OP